Automobile Coatings: Powder Coating & Electrocoating Specialists

Welcome To Powder Cote II, Tennessee

Powder Coating & Electrocoating Experts

Welcome to Powder Cote II in Tennessee. We are Powder Coating & Electrocoating specialists. We started in Mt. Clemens, Michigan and expanded to Tennessee. This is a new standard in automotive component finishing. Our expertise is on display in our facilities. We have over 300,000 sq ft in Michigan and 140,000 sq ft in Tennessee. We are all about innovation, quality and customer satisfaction. We are a Tier I and Tier II supplier in many industries.

Our Tennessee facility is not our second facility, it’s a sign of our growth and commitment to this industry. It represents our growth and commitment to the industry. Our recent $3.5M expansion allowed us to serve Southern and Midwestern auto manufacturers. We will be adding 10% to our workforce as a result. This is our commitment to economic growth and service excellence. At Powder Cote II we are your partner in success. We make sure every project benefits from our full powder coating and e-coating expertise. Consistent and predictable coating thickness is key in our processes for functionality and appearance.

Powder Cote II specializes in providing high-quality paint-finishing solutions, catering to a diverse range of industries with expertise and precision.

Our Services

We offer a comprehensive range of ecoating and powder coating services that provides exceptional corrosion resistance.

Industries We Serve in the Coating Sector

Automotive

Agricultural

Industrial

Our Coating Services

Powder Cote II offers a comprehensive range of ecoating and powder coating services. This includes not only assembly and tooling, but also testing and transportation, seamlessly integrating each aspect to provide a complete solution.

Additionally, we provide professional powder coating services and encourage potential customers to contact our team for quotes related to their projects. Consequently, we have become the trusted choice for businesses seeking top-quality paint finishing

Coating Processes

Powder Coating Process Overview

The powder coating process is a sophisticated dry application method that ensures a uniform, cured finish. It begins with meticulous surface preparation, where the material is cleaned and pre-treated to guarantee optimal adhesion. Following this, a specialized spray gun is used to apply the dry powder. This spray gun emits electrostatic waves, causing the powder particles to adhere to the material’s surface. The powder itself contains curing agents and epoxy resin, which are crucial for the coating and finishing process. Once the powder is applied, the material is baked in an oven, allowing the powder to cure and form a thicker, more durable finish. This method not only enhances the aesthetic appeal but also provides robust protection against wear and tear.

E Coating Process Overview

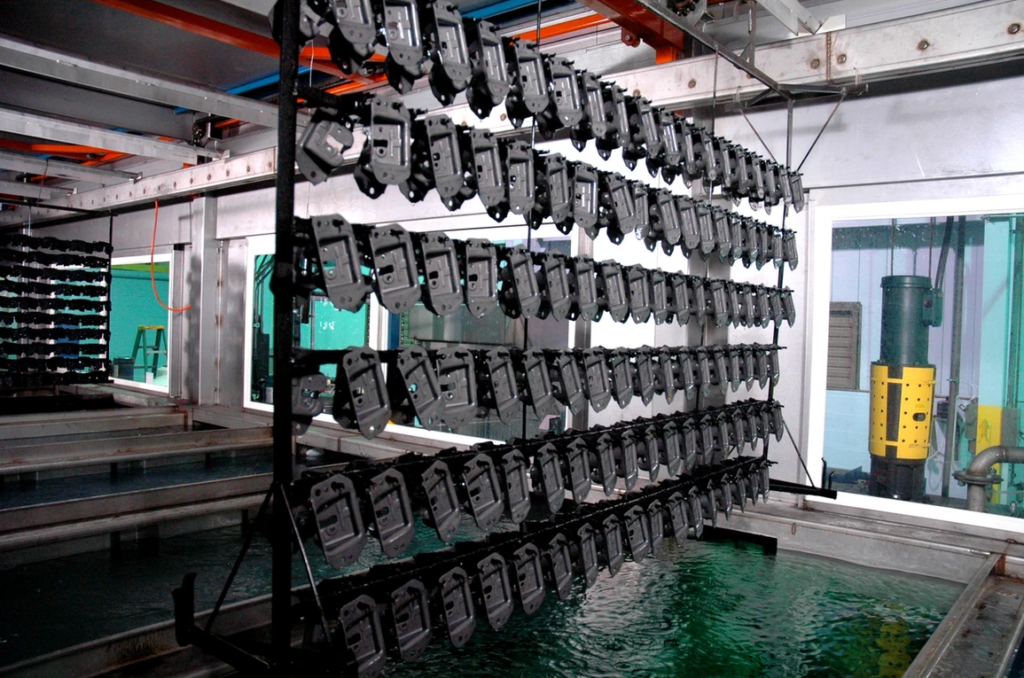

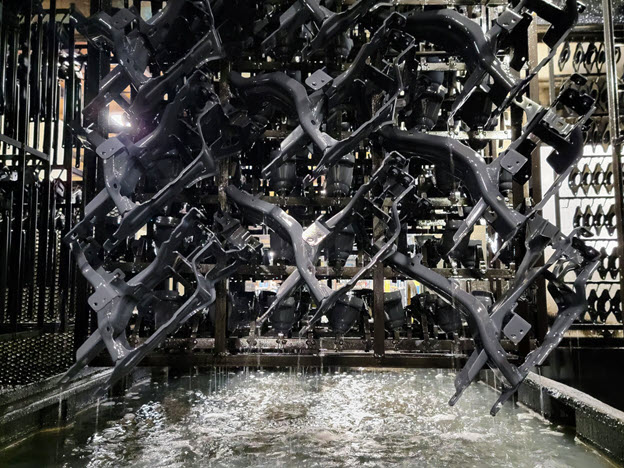

The e-coating process, also known as electrocoating or electropainting, is a precise wet application method. It involves submerging the material in a bath filled with a water-based solution. This bath is electrically charged, which causes the paint particles in the solution to adhere uniformly to the material’s surface. The thickness of the coating can be meticulously controlled by adjusting the duration the material spends in the bath or by varying the electrical charge’s voltage. After the material is removed from the bath, it undergoes a curing process in an oven, resulting in a hardened, durable finish. This method ensures a consistent, thin coat that provides excellent coverage, even in hard-to-reach areas.

Powder Cote II commitment to excellence, supported by years of hands-on experience in electrocoating and powder coating, has led to a proven track record of delivering superior results. solutions.

Our team of skilled coating professionals is dedicated to ensuring that every project meets the highest standards of precision and efficiency.

Protection against harsh environmental conditions

When choosing a coating for products exposed to harsh conditions, uv resistant powder coating offers significant advantages due to its durability and protection against environmental factors like wear and UV exposure. Additionally, e-coating provides superior corrosion resistance, making it essential for applications where corrosion resistance is a critical factor.

Coating Performance and Durability

UV Resistance and Coating Performance

When it comes to UV resistance, powder coatings stand out as the superior choice. Powder coatings are available in a variety of UV-resistant formulas, making them ideal for products that are frequently exposed to sunlight and other elements. This UV resistance helps maintain the coating’s appearance and integrity over time, preventing degradation and discoloration. On the other hand, most e-coats are not inherently UV stable, which can lead to issues with longevity and appearance when exposed to UV light. However, there are specialized e-coating formulas designed to offer improved UV resistance, suitable for specific applications. Ultimately, the decision between powder coating and e-coating depends on the project’s specific requirements, including the level of UV exposure and the desired degree of corrosion protection. By carefully considering these factors, you can choose the coating that best meets your needs for durability and performance.