E Coated: An Introduction to Electrocoating

Electrocoating (E Coat) is a sophisticated coating process tailored for the precision demands of the automotive component manufacturing sector. This method uses a specialized coating solution and electrical current to ensure uniform paint deposition onto both individual components and complete assemblies, even those with intricate designs and stringent performance criteria. This guarantees not just accuracy but also consistency in coating thickness. Gain a better understanding of how E Coat provides superior corrosion protection by visiting this BASF Coating.

Why Choose Our E Coat Services Near You

The Advanced E Coat Process

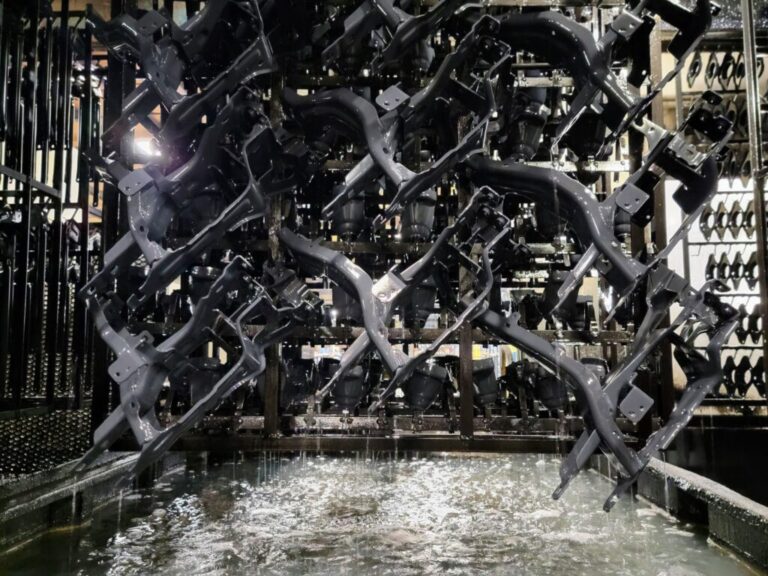

Our advanced electro coat finishing process integrates a comprehensive 13-stage zinc phosphate pretreatment designed explicitly for automotive components. Additionally, we utilize cathodic epoxy as a primer due to its superior adhesion and corrosion protection properties.

Furthermore, our state-of-the-art electrocoat application employs an automatic voltage control system with a direct power source, immersing metal parts in a bath containing oppositely charged paint particles. This combination ensures a consistent film thickness across any component size, ensuring optimal performance and durability for every automotive piece we treat.

The e coating process we use is a modern, efficient technique that combines attributes of both painting and plating, providing uniform protection and aesthetic appeal.

Quality Assurance in Electro Coating

Ensuring Excellence in Every Layer

At our facility quality is at the forefront of our E Coat process. Learn more about our Quality Assurance. Each layer of coating is meticulously tested and monitored to meet the highest standards of the automotive industry.

The resulting paint film adheres uniformly to metal surfaces, providing exceptional hardness and durability.

Comprehensive Testing for Electrocoat Perfection

Testing for Durability, Performance, and Corrosion Resistance

To ensure that our electro coated components stand the test of time, we conduct rigorous testing procedures. From adhesion tests to corrosion resistance evaluations, we leave no stone unturned in validating the quality of our electrocoating services.

The electrocoating process involves using electrical currents to attract charged paint particles to metal surfaces, ensuring a uniform coating that enhances performance and anti-corrosive properties.

Transportation: Delivering Excellence to Your Doorstep

Streamlined Logistics for Your E Coating Needs

Understanding the importance of timely delivery in the automotive industry, our Transportation Services are optimized to ensure that your electro coated components reach you safely and on schedule.

Discover More About Us

Leading the Way in Electro Coating Technology

To learn more about our journey, vision, and commitment to excellence in electrocoating, we invite you to visit our About Us page.

Our advanced electrocoating technology utilizes positively charged paint particles, which are attracted to negatively charged metal surfaces, ensuring uniform paint application and superior corrosion resistance.

Your Trusted Partner in Electro Coat

Commitment to Excellence and Innovation

As leaders in the electro coating industry, we are dedicated to providing innovative solutions and unparalleled quality in every project. Our E-coating process ensures that paint particles are uniformly attracted to the bare metal surface, providing excellent coverage and protection. Whether you’re looking for ‘E Coat near me’ or seeking expert guidance in electro coating, we are here to help. The metal part is immersed in a paint bath, where an electrical current facilitates the application of paint, ensuring strong adhesion and a high-quality finish. Contact us today to learn more about our services and how we can assist in your automotive component manufacturing needs. Additionally, while powder coating has its uses, it often struggles with uniformity in hard-to-reach areas, making E-coat a superior choice for complete, protective finishes.