HFBEC vs E-Coating: Advantages of High Film Build Electrocoating (HFBEC)

Electrocoating, commonly known as e-coating or e coat, has long been a go-to method for applying protective and decorative finishes to various products and components. Traditional e-coating has been a staple in the automotive, aerospace, and appliance industries. Still, the emergence of High Film Build Electrocoating (HFBEC) has ushered in new possibilities and challenges in the world of corrosion protection and coating technology.

When comparing e coating and High Film Build Electrocoating methods, it is essential to consider their unique advantages, applications, and environmental impacts. In this blog post, we’ll delve into the distinctions, benefits, and applications of HFBEC compared to traditional e-coating.

What is Electrocoating (E-Coating)?

Definition and Process Overview

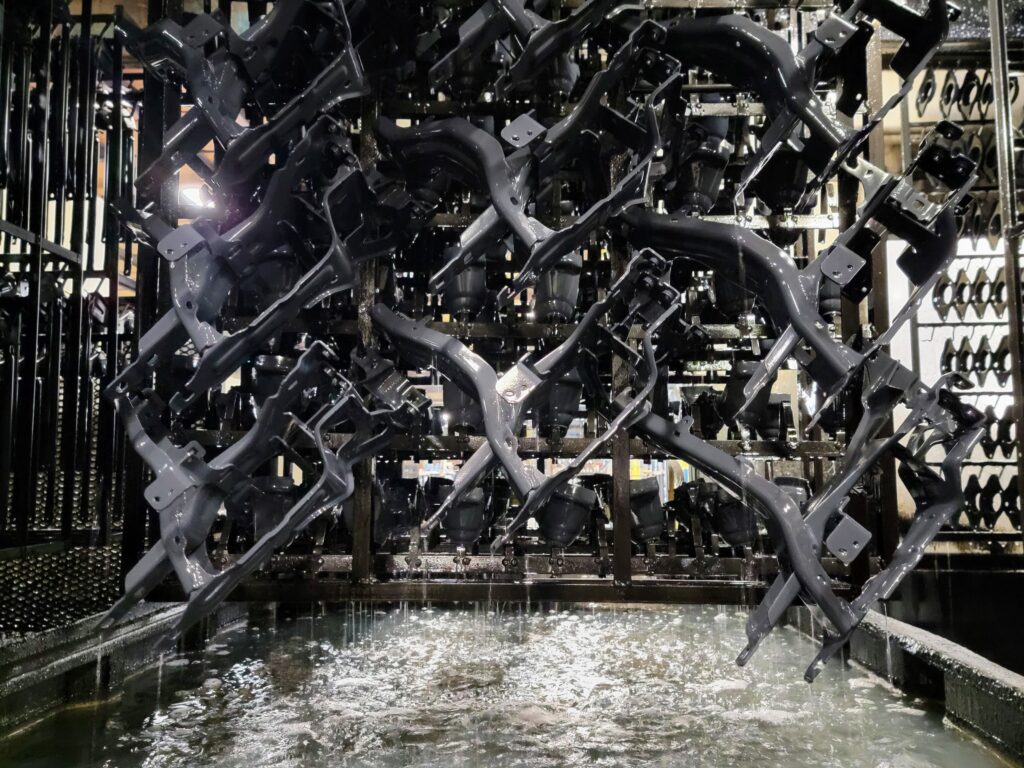

Electrocoating, also known as e-coating, is a sophisticated surface finishing process that involves immersing a part in a water-based paint solution and applying an electric current to deposit paint particles onto the surface. This method is widely adopted across various industries, including automotive, aerospace, and household appliance manufacturing, due to its efficiency and effectiveness. The e-coating process comprises several critical steps: surface preparation, immersion in the paint solution, and curing in an oven. The electric current ensures that the paint particles are uniformly distributed and deposited onto the surface, resulting in a consistent coating thickness. This meticulous process guarantees a high-quality finish that enhances both the appearance and durability of the coated parts.

Benefits of E-Coating in Surface Finishing

E-coating offers numerous advantages in surface finishing, making it a preferred choice for many industries. One of the primary benefits is its superior corrosion resistance, which significantly extends the lifespan of coated parts. The process also provides exceptional durability, ensuring that the coating can withstand harsh environmental conditions. Additionally, e-coating delivers a high-quality finish that is both aesthetically pleasing and functional. This method is particularly effective for coating complex shapes and hard-to-reach areas, ensuring comprehensive coverage and protection. Moreover, e-coating is an environmentally friendly process that produces minimal waste and emissions, aligning with sustainable manufacturing practices.

Traditional E-Coating Process: An Overview

Advantages of Traditional E-Coating

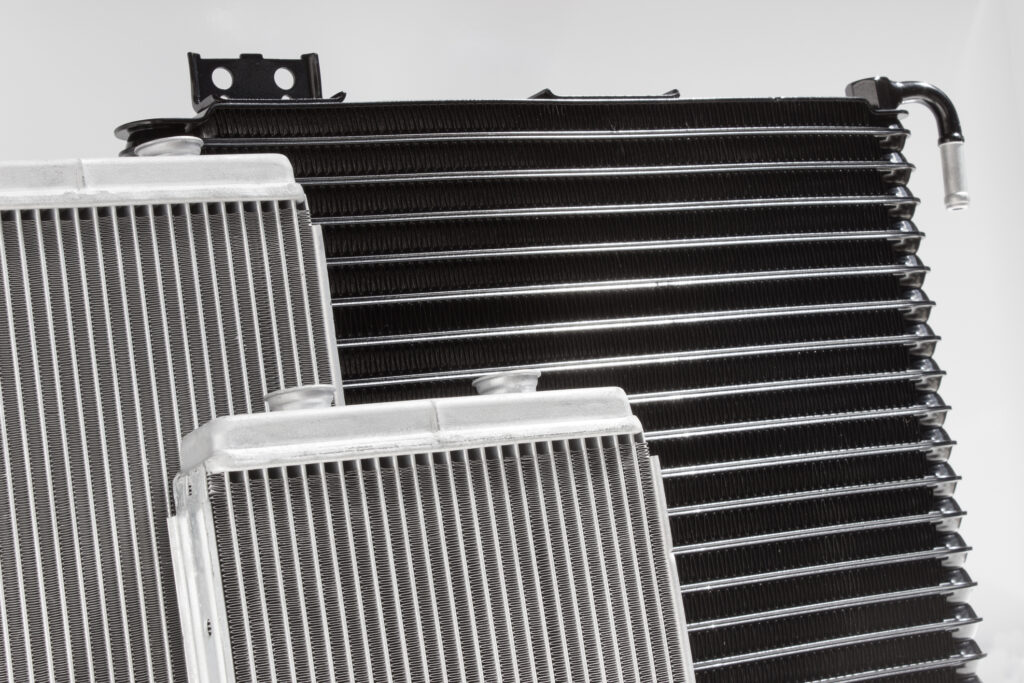

1. Corrosion Protection: Traditional e-coating offers outstanding corrosion protection due to its uniform coverage of the substrate, ensuring protection and durability across the entire surface of complex geometries and products with uneven surfaces.

2. Cost-Effective: It’s a cost-effective method for coating large volumes of parts in mass production.

3. Environmentally Friendly: The use of water-based formulations makes it eco-friendly with minimal volatile organic compounds (VOCs).

Challenges of Traditional E-Coating

1. Limited Film Thickness: Traditional e-coating has limitations when it comes to achieving high film build, making it less suitable for applications requiring a thicker coating. Powder coating, on the other hand, generally results in a thicker coating, typically ranging from 50 to 100 microns, which enhances durability and aesthetic appeal.

2. Limited Color and Appearance Options: It’s primarily used for functional purposes, limiting the choices for color and appearance.

Surface Preparation for E-Coating

Importance of Surface Preparation

Surface preparation is a pivotal step in the e-coating process, as it directly impacts the quality and effectiveness of the final coating. The surface of the part must be meticulously cleaned and free of contaminants, oils, and other substances that could interfere with the coating process. Proper surface preparation ensures that the paint particles adhere evenly to the surface, resulting in a uniform and consistent coating thickness. This process typically involves several stages, including cleaning, degreasing, and etching the surface to create a strong bond between the coating and the substrate. By ensuring a clean and well-prepared surface, manufacturers can achieve superior corrosion resistance and a high-quality finish that meets stringent industry standards.

Electrocoating High Film Build (HFBEC): The Innovation

Advantages of HFBEC: Superior Corrosion Resistance

1. High Film Thickness: HFBEC can achieve much thicker coatings, suitable for applications where enhanced corrosion resistance, durability, or aesthetics are required. The use of a spray gun in the application process ensures even distribution and strong adhesion of the coating material.

2. Customization: HFBEC offers greater flexibility in appearance options, making it suitable for decorative and functional applications.

3. Enhanced Edge Coverage: It provides improved edge coverage, reducing the risk of corrosion at sharp edges and corners.

4. Reduced Environmental Impact: HFBEC can be formulated with low or zero-VOC coatings, making it environmentally friendly.

5. Excellent Adhesion: HFBEC typically offers excellent adhesion to various substrates, including ferrous and non-ferrous metals.

Applications of HFBEC: Coating Thickness

1. Automotive Industry: HFBEC is used for durable and corrosion-resistant coatings on vehicle bodies, chassis components, and underbody parts. Additionally, powder coat is applied to enhance performance and visual appeal, often in combination with e-coat for optimal protection and longevity.

2. Appliances: It’s applied to household appliances for both functional and aesthetic purposes.

3. Architectural and Construction: HFBEC is used for architectural elements like window frames, fencing, and structural steel to enhance longevity and appearance.

4. Industrial Equipment: It’s employed on heavy machinery and equipment exposed to harsh environmental conditions.

5. Consumer Goods: HFBEC provides decorative and protective coatings on various consumer goods.

Conclusion

Electrocoating has evolved significantly, with High Film Build Electrocoating (HFBEC) offering enhanced capabilities and versatility. While traditional e-coating remains a reliable choice for many applications, HFBEC opens doors to thicker coatings, increased customization, and improved performance. As technology advances, so will the possibilities for electrocoating, expanding its applications and benefits further. Choose the right electrocoating method for your specific needs, and enjoy the benefits of superior corrosion protection and aesthetics.